Industries using equipment, transportation, or energy production need fuel management. Effectively managing fuel use and flow not only maximizes running expenses but also improves safety, lowers environmental impact, and guarantees consistent output. Advanced fuel monitoring and distribution systems have become essential as demand for accuracy and automation increases. Among these developments, systems using smart sensors, real-time monitoring, and automatic flow adjustments are changing how companies manage fuel activities.

Efficient Fuel Management: Why It Is Required

Controlling fuel poses several difficulties for contemporary businesses. Adopting methods ensuring accountability and efficiency is vital given erratic fuel prices, more regulatory attention, and the requirement for operational transparency. Manual meter readings or regular audits, for instance, are classic ways that can lead to mistakes, delays, and even misuse. Unexpected outages, higher costs, and a detrimental effect on general productivity can result from these constraints.

By giving precise monitoring, reporting, and control over fuel consumption, a thorough fuel management system helps to overcome these difficulties. Businesses can spot trends, spot leaks or irregularities, and make sure fuel is used to its fullest extent by combining sophisticated analytics with automatic monitoring equipment. This forward-thinking strategy reduces waste, guards against illegal access, and keeps operations running smoothly.

Modern Fuel Management Systems Operate in What Way

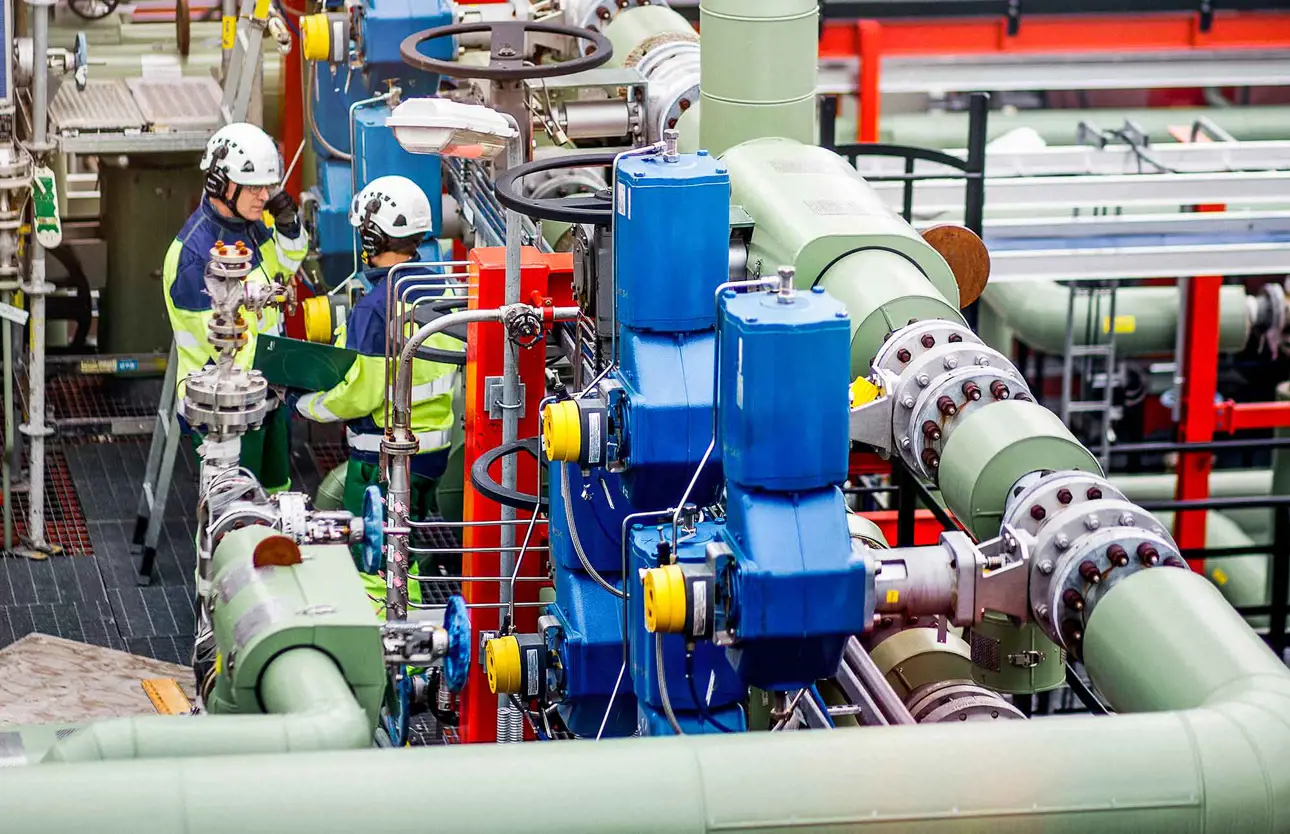

Usually, a fuel management system monitors and controls fuel flow using both hardware and software elements. Parameters including volume, pressure, and temperature are measured by sensors placed at fuel tanks, pipelines, or dispensing locations. The results of this analysis and real-time reporting are sent to a centralised control unit or cloud-based platform.

Modern systems frequently combine the following important elements:

Automated dispensing systems let fuel be precisely measured and assigned to particular vehicles or equipment.

Real-time monitoring Offering rapid fuel level, consumption trend, and anomaly updates.

Notifications and alerts – Informing operators of leaks, system faults, or odd use patterns.

Reporting and data analysis – Providing practical ideas for maximizing fuel use and spotting inefficiencies.

Companies can use these tools to make sure fuel is only dispensed when it’s okay and used efficiently, which greatly lowers waste and costs of running things.

Advantages of Perfect Fuel Control

A good fuel management system provides several advantages in several industries:

Cost Optimization

In sectors like energy, logistics, and transportation, fuel makes up a sizable chunk of running costs. A fuel management system directly affects the bottom line by carefully tracking usage and cutting losses. Companies may pinpoint areas of too high consumption, maximize routes or usage patterns, and more precisely estimate fuel needs.

Improved Accountability and Security

In big fleets or industrial settings, unauthorized fuel usage is frequent. Fuel management systems stop theft by limiting access, tracking transactions, and producing user-specific reports. This responsibility guarantees that every drop of fuel is traceable, therefore discouraging abuse and encouraging responsible behavior.

Environmental Sustainability

Effective fuel economy helps to preserve the environment. Businesses cut fuel spillage risks and carbon emissions by maximizing use and minimizing waste. This fits with business sustainability objectives and escalating environmental rules.

Operational Efficiency

Fuel scarcity or bad management can cause downtime that will throw off the manufacturing schedule and result in money losses. A smooth system guarantees constant fuel supply and availability, therefore enabling continuous operations and increased productivity.

Including Innovative Flow Controls

Modern fuel systems include sophisticated flow controls more and more in order to maximize accuracy and efficiency. By controlling the pace at which fuel is supplied, these systems help to keep constant pressure and flow rates even under different situations. This not only guarantees correct measurement but also safeguards the infrastructure and equipment from damage brought on by overflows or pressure spikes.

Advanced flow control lets operators dynamically change fuel delivery depending on demand, vehicle type, or operational needs. Combining these checks with automated reporting and real-time monitoring helps companies to reach hitherto unheard-of fuel allocation accuracy, hence avoiding losses and maximizing resource utilization.

Practical uses in real life

Many different sectors can benefit from fuel management systems. Some of the main uses are:

Fleet managers can track fuel use for every vehicle, distribute fuel depending on route needs, and stop illegal refueling.

Maintaining continuous operation of equipment depends greatly on on-site fuel storage and distribution. Automated systems reduce human mistakes and guarantee prompt delivery.

Energy and Utilities: Fuel management in power plants or backup generators guarantees dependable operations and minimizes the possibility of leaks and waste by controlling fuel use.

In the aviation and marine industries, compliance with safety standards, effective operations, and cost reduction depend on exact fuel management.

Choosing the Best Fuel Management System

Companies choosing a fuel management system have to weigh a few elements to guarantee optimum efficiency:

Scalability– The system ought to let development as the company expands fit the present fleet or operations.

Integration Capacities—Compatibility with current tools, reporting systems, and equipment guarantees smooth integration.

User-friendliness: A clean reporting interface improves usefulness and lowers training needs by its simplicity.

Sensors, controllers, and software have to work consistently in different kinds of environments.

Cost-Effectiveness: The amount of money you put in at first and how much it costs to keep it running should be weighed against how much money you could save on fuel and how well it works.

A smart choice that pays off in the form of long-term operational savings, better safety, and higher productivity is investing in a fuel management system.

Future Developments in Fuel Management

Data analytics and technology continue to propel the development of fuel management systems. Among the new trends are:

Enabled monitoring: Smart sensors linked via the Internet of Things (IoT) offer more fine-grained and remote access to fuel information.

Artificial intelligence systems examine fuel usage patterns, forecast future consumption, and provide maximizing methods using artificial intelligence.

Mobile Access and Automation – Operators may use mobile devices to check fuel systems, approve dispensing, and get alarms, guaranteeing flexibility and quick response.

Sustainability Integration: Advanced systems meant to help greener operations are more and more meant to include hybrid energy solutions, biofuels, or renewable fuels.

These developments show how technology is driving a move toward totally automated, smart fuel management systems that progressively enhance accuracy and efficiency.

Conclusion

Maximizing fuel consumption is now more crucial than ever in the cutthroat, cost-conscious modern industrial environment. A good fuel management system saves money and helps the environment by providing accurate monitoring, simplified procedures, and more security, hence lowering environmental impact. Modern developments like improved flow controls help companies to attain perfect fuel management that encourages ongoing productivity, responsibility, and sustainability.

Any company striving for operational excellence and long-term fuel management efficiency must now install such systems; it is no longer only a choice.