Quick Research Snapshot

The bullet points below summarize essential scientific aspects of wafer-related thermal and material properties. These factors form the backbone of advanced experiments in electronics, optics, and applied physics.

● Thermal Conductivity: Governs heat dissipation in microelectronics

● Coefficient of Thermal Expansion (CTE): Impacts device reliability under temperature cycling

● Lattice Stability: Determines performance at extreme operating conditions

● Surface Energy: Influences thin-film deposition and bonding strength

● Mechanical Strength: Essential for high-yield manufacturing and experimental handling

Thermal Management Challenges in Semiconductor Science

A semiconductor silicon wafer is not merely a mechanical platform—it is a thermally active substrate whose temperature stability directly influences device performance. In scientific experiments, maintaining a uniform thermal profile is essential to prevent data distortion caused by localized heating or thermal drift.

Silicon, the dominant material for wafer production, offers a high degree of thermal conductivity compared to many metals used in electronics. However, as device geometries shrink to the nanoscale, heat dissipation becomes more challenging, making wafer thermal properties a research priority.

Heat Flow and Scientific Experiments

Thermal gradients across a wafer can alter dopant activation, thin-film stress, and optical alignment. In photonic and MEMS research, these gradients can shift resonant frequencies or cause mechanical deformation, leading to false experimental conclusions.

Material Science Principles Applied to Wafers

The study of semiconductor wafers involves multiple branches of material science, including crystallography, surface chemistry, and defect physics. These disciplines converge to optimize wafer performance for both research and industrial applications.

Crystallographic Perfection

Single-crystal wafers have minimal grain boundaries, reducing scattering of charge carriers and phonons. This perfection is vital for experiments in quantum devices and precision sensors, where even a minor defect can impact outcomes.

Surface Chemistry and Interface Control

In experiments requiring thin-film growth, the wafer’s surface chemistry dictates nucleation behavior. Scientists may use oxidation, hydrogen passivation, or chemical functionalization to control surface states, thereby influencing adhesion, growth rates, and defect formation.

Beyond Silicon: Material Variants in Scientific Use

While silicon dominates, certain experiments require alternate wafer materials to achieve specific physical properties. A semiconductor wafer made from compound semiconductors like gallium arsenide (GaAs) or indium phosphide (InP) can offer direct bandgap properties ideal for optoelectronic research.

Notable Alternative Materials:

● Gallium Nitride (GaN): High breakdown voltage and efficiency for power electronics research

● Sapphire (Al₂O₃): Excellent optical transparency and thermal stability for photonics

● Germanium (Ge): Superior carrier mobility for infrared sensors and solar cells

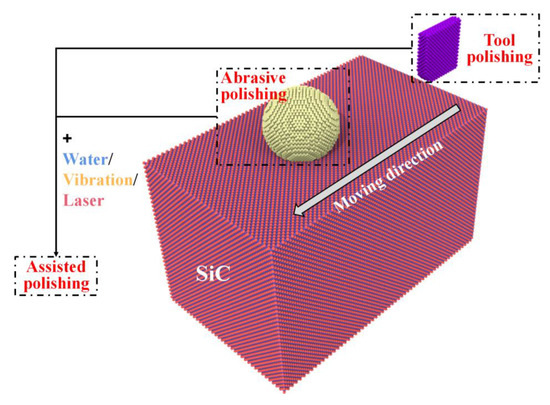

● Silicon Carbide (SiC): Exceptional thermal conductivity for high-temperature studies

Each material choice reflects a trade-off between mechanical strength, thermal performance, and electronic properties, tailored to the experiment’s objectives.

Mechanical and Thermal Interactions

The mechanical strength of wafers must balance flexibility with resistance to fracture. Thermal cycling during experiments can induce stress, leading to wafer warping or microcracking if the coefficient of thermal expansion is mismatched with deposited materials.

Managing Thermal Expansion Mismatches

When wafers are coated with materials of different thermal expansion rates, temperature changes can create mechanical stress. This is a common concern in heteroepitaxial growth, where a film and substrate expand at different rates, potentially generating dislocations or delamination.

The Role of Wafer Properties in Device Prototyping

In research prototypes, wafer properties determine whether an experiment transitions successfully to functional demonstration. The thermal and mechanical performance during initial trials often dictates the feasibility of scaling a concept for further study.

Example: MEMS Resonators

For MEMS devices like resonators, any thermal distortion in the wafer can alter vibrational modes, detuning the device. Precise wafer selection and conditioning are necessary to maintain frequency stability across operational temperatures.

Advances in Wafer Thermal Engineering

Modern research pushes wafer engineering beyond simple heat dissipation toward active thermal control. Scientists are integrating microfluidic cooling channels directly into wafer structures, using techniques like deep reactive-ion etching (DRIE) to create embedded heat management systems.

Key Thermal Innovations

● Low-Thermal-Resistance Substrates: Enhance heat transfer away from hotspots in high-power devices

● Integrated Cooling Layers: Use embedded metal microchannels for rapid heat removal

● Phase-Change Materials: Stabilize temperature through latent heat absorption

● Nanostructured Surfaces: Increase surface area for improved radiative cooling

These developments directly support scientific experiments where thermal stability is as critical as electrical performance.

Measurement Techniques for Wafer Thermal and Material Properties

Understanding wafer behavior under different conditions requires precise measurement tools.

Common Techniques Include:

● Thermal Reflectance Imaging: Maps surface temperature distribution in real time

● Laser Flash Analysis: Determines thermal diffusivity and conductivity

● Nanoindentation: Measures mechanical hardness and modulus under controlled conditions

● X-ray Diffraction (XRD): Evaluates crystal strain caused by thermal cycling

Each technique provides data that influences wafer preparation for experiments, ensuring that materials behave predictably under operational stresses.

Conclusion

The interplay of thermal dynamics, mechanical integrity, and material science defines the role of semiconductor wafers in modern research. Far from being passive supports, wafers are active participants in scientific experiments, influencing results through their physical and chemical properties. By refining thermal management, enhancing material compatibility, and exploring new substrate compositions, scientists can create wafers that enable increasingly ambitious experiments in electronics, optics, and quantum technologies. This constant evolution ensures that wafers remain a critical enabler of scientific progress in the decades ahead.