Key Takeaways

- Temperature and humidity dramatically influence the performance and longevity of adhesives.

- Choosing the right adhesive for an environment is critical for durability and reliability.

- Environmental factors such as UV radiation and chemical exposure further impact adhesive bonds.

- Practical mitigation strategies can help maintain adhesive effectiveness over time.

Table of Contents

- Temperature’s Impact on Adhesive Performance

- Humidity’s Role in Adhesive Durability

- Combined Effects of Temperature and Humidity

- Environmental Factors Beyond Temperature and Humidity

- Strategies to Mitigate Environmental Effects

- Final Thoughts

Introduction

Adhesives are essential in diverse sectors, from automotive manufacturing to electronics assembly. Their ability to create durable and reliable bonds underpins the integrity of many modern products. However, these bonds don’t exist in a vacuum—environmental conditions such as temperature and humidity can drastically affect adhesive performance, sometimes leading to costly premature failures. Understanding these variables improves product quality and saves time and resources in every industry that depends on consistent adhesive strength and flexibility. To ensure efficient and long-lasting results, it’s vital to consider the right tools and systems, such as hot melt adhesive equipment, when selecting and applying adhesives.

Rising demand for high-performance adhesives places increased emphasis on research and innovation, highlighting how sensitive many adhesives can be to small shifts in their operating environment. The right combination of adhesive formula and application method is crucial, especially as products are exposed to harsher conditions during their lifetime.

Temperature’s Impact on Adhesive Performance

Temperature is a primary driver of changes in adhesive behavior. Many commercial adhesives are formulated to operate within a certain temperature range, and deviation from these ranges can be problematic. At low temperatures, adhesives may become brittle. Their loss of elasticity in cold conditions often means decreased strength, higher risk of cracking, and eventual bond failure. Hot temperatures, on the other hand, tend to accelerate molecular motion within the adhesive. This can cause softening, reduced bond strength, and permanent loss of adhesive function if temperatures are extreme or sustained.

Industries with outdoor or high-heat processes must be especially aware of these issues. For example, the construction industry often uses adhesives for structural elements, which can be compromised in extremely hot summers or cold winters.

Humidity’s Role in Adhesive Durability

Humidity introduces another layer of complexity. Moisture in the air can permeate adhesive bonds or interact with both the adhesive and substrate. When high humidity, many adhesives absorb water molecules, which can cause swelling, softening, or hydrolytic degradation. This is especially critical for applications involving porous materials, like wood or textiles, where moisture uptake can be swift and damaging.

Certain adhesive chemistries are more susceptible than others. Water-based and some pressure-sensitive adhesives may significantly reduce hardness and resistance to future temperature extremes when exposed to moist environments. Furthermore, excess humidity can hinder the curing or bonding process in the early stages, leading to weak or incomplete bonds and raising the risk of early failure.

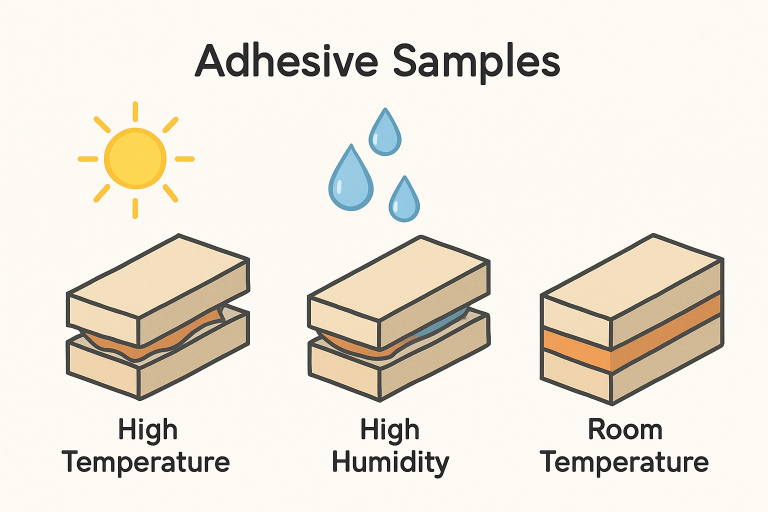

Combined Effects of Temperature and Humidity

The combination of temperature fluctuations and elevated humidity levels poses an even more severe threat to adhesive stability. Physical and chemical degradation speed up when adhesives are exposed to heat and moisture simultaneously. This can result in a rapid drop in adhesive viscosity, premature setting or curing, and loss of flexibility—all of which increase the risk of delamination or bond separation.

Climate-controlled environments help, but are not always practical, especially in fieldwork or applications subject to outdoor conditions. For long-term results, selecting adhesives tested specifically under combined stress conditions is essential. As noted by Engineering Toolbox, testing adhesives against combined environmental stresses provides the most realistic estimate of service performance.

Environmental Factors Beyond Temperature and Humidity

While temperature and humidity are critical, the environment can contain other hazards to adhesive durability. Exposure to UV radiation, primarily from sunlight, breaks down the chemical structure of many common adhesive polymers, leading to surface cracking or yellowing. Chemical pollutants, such as solvents, cleaning agents, or industrial fumes, can react with adhesives and degrade them either on the surface or at the molecular level.

Industries like automotive and aerospace often employ specialized coatings or encapsulants to shield sensitive adhesive bonds from harmful external agents. Considering the environmental context of adhesive use is necessary for effective, long-term product design.

Strategies to Mitigate Environmental Effects

Storage and Application Controls

The first line of defense is environmental control during storage and application. Maintaining stable temperatures and lower humidity levels ensures adhesives retain optimal properties until the point of use. Keeping containers tightly closed and using desiccants in storage areas can help protect against premature moisture exposure.

Choosing the Right Adhesive Formula

Modern adhesive technologies offer solutions tailored to environments with severe stress factors. Manufacturers now formulate adhesives with additives for UV resistance, greater thermal tolerance, and improved hydrolytic stability. Carefully reading manufacturer technical data sheets and conducting in-situ trials can help users identify products with the right blend of properties.

Regular Inspection and Maintenance

Routine inspection is an often-overlooked strategy. Catching small changes in bond appearance or flexibility early can prevent catastrophic failures. For critical applications, using sensor technologies to monitor environmental conditions around adhesive bonds provides real-time data that can inform maintenance needs before integrity is compromised.

Final Thoughts

Temperature, humidity, and environmental influences each play an outsized role in adhesives’ long-term durability and effectiveness. By understanding these factors and implementing practical mitigation steps—from climate control during storage, to choosing advanced adhesive formulas, and performing regular inspections—industries can vastly improve the performance and lifespan of bonded assemblies. A proactive approach translates to enhanced safety and reliability, significant long-term cost savings, and improved end-product quality.